CNC turning is a pivotal manufacturing process that shapes raw materials into precise, cylindrical components used across industries like aerospace, automotive, medical, and electronics. By leveraging computer-controlled automation, CNC turning delivers high accuracy, repeatability, and efficiency, making it a cornerstone of modern production. This article provides a clear and comprehensive introduction to CNC turning, exploring its mechanics, operations, applications, and benefits.

Understanding CNC Turning

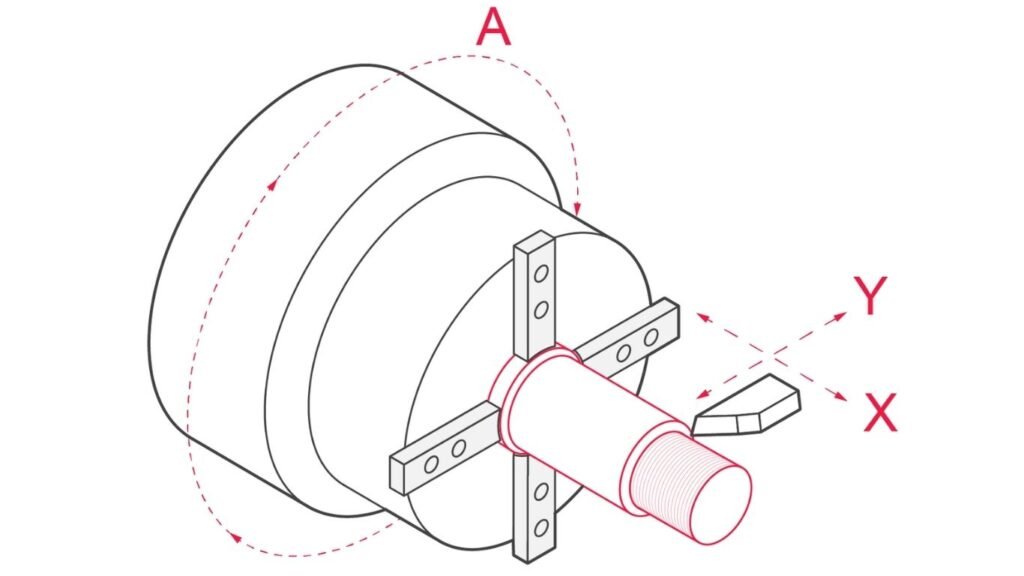

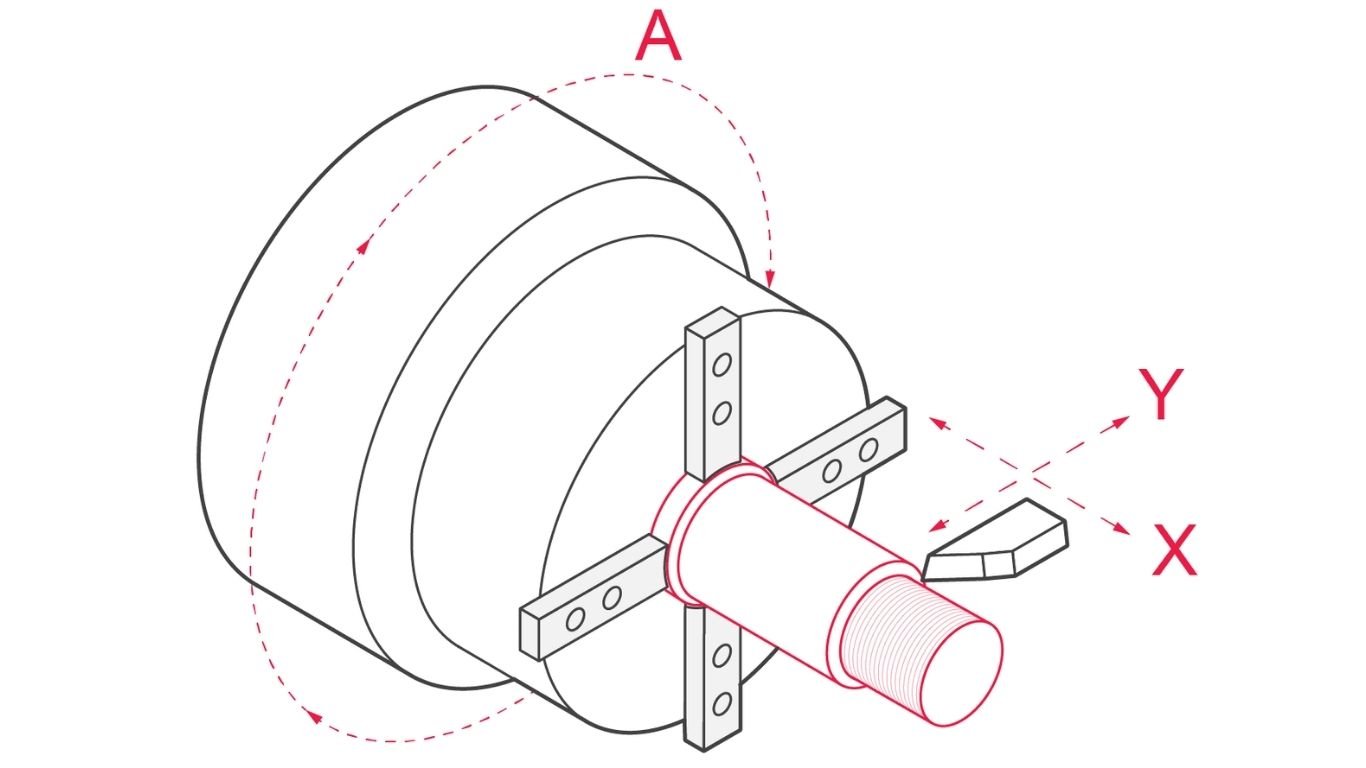

CNC turning, or Computer Numerical Control turning, is a subtractive manufacturing process where a stationary cutting tool removes material from a rotating workpiece. The workpiece, typically a cylindrical bar or stock, is secured in a chuck and spun at high speeds while the tool shapes it into the desired form. The “CNC” aspect refers to the computer automation that guides the tool’s movements, ensuring precision and consistency.

Unlike manual lathes, CNC turning machines interpret digital instructions (G-code) derived from CAD (Computer-Aided Design) files, enabling complex geometries with minimal human intervention. This process excels at producing axially symmetric parts, such as shafts, bolts, and pulleys, with tight tolerances often as precise as ±0.001 inches.

How CNC Turning Works

The CNC turning process involves several key steps:

- Design Creation: A part is designed using CAD software like AutoCAD or SolidWorks, specifying dimensions and features.

- Program Generation: The CAD file is converted into a CAM (Computer-Aided Manufacturing) file, which generates G-code to instruct the CNC machine.

- Machine Setup: The workpiece is mounted in the machine’s chuck, and appropriate cutting tools are loaded into the tool turret.

- Machining: The spindle rotates the workpiece, and the cutting tool moves along one or more axes to remove material, shaping the part per the G-code.

- Inspection: The finished part is checked for accuracy and quality, ensuring it meets design specifications.

CNC turning machines can operate in horizontal or vertical orientations. Horizontal lathes are common for smaller parts, while vertical lathes handle larger, heavier workpieces, aligning the material’s center of gravity with the rotational axis for stability.

Key Components of a CNC Turning Machine

A CNC turning machine comprises several essential components:

- CNC Control Panel: The interface for inputting and managing G-code, controlling tool movements and speeds.

- Spindle: Rotates the workpiece at precise speeds, critical for accurate machining.

- Chuck and Collet: Secure the workpiece; chucks handle various shapes, while collets provide precision for smaller parts.

- Tool Turret: Holds multiple cutting tools, allowing quick changes for diverse operations.

- Headstock and Tailstock: Support the workpiece, with the headstock driving rotation and the tailstock stabilizing longer pieces.

- Lathe Bed: The rigid base ensuring component alignment and smooth operation.

- Carriage: Moves the cutting tool along the workpiece for precise positioning.

Types of CNC Turning Machines

CNC turning machines vary in design and capability:

- Horizontal CNC Lathes: Ideal for small to medium parts, offering high precision for applications like automotive components.

- Vertical CNC Lathes: Suited for heavy, large-diameter workpieces, such as gears and flywheels, with enhanced stability.

- Turning Centers: Advanced machines combining turning with milling, drilling, and tapping, perfect for complex parts in aerospace and robotics.

CNC Turning Operations

CNC turning supports a range of operations to create diverse part features:

- Turning: Shapes the outer diameter to form cylinders or tapers.

- Facing: Creates a flat surface at the workpiece’s end.

- Grooving: Cuts recesses for O-rings or aesthetic features.

- Parting: Separates the finished part from the stock.

- Threading: Forms internal or external threads for fasteners.

- Drilling: Creates holes along or off the rotational axis.

- Boring: Enlarges and refines existing holes.

- Knurling: Impresses a textured pattern for grip.

- Hard Turning: Machines high-hardness materials, replacing grinding in some cases.

Advanced turning centers with live tooling can perform milling or polygonal turning, creating non-circular shapes like hexagons.

Materials Used in CNC Turning

CNC turning is compatible with a wide range of materials, each chosen based on the part’s intended use:

- Metals: Aluminum (lightweight, corrosion-resistant), steel (durable), brass (low-friction), copper (conductive), and titanium (high-strength).

- Plastics: Nylon, polycarbonate, ABS, and PEEK for cost-effective, versatile components.

- Composites and Wood: Used for specialized applications like decorative or lightweight parts.

Material properties influence machining parameters, tool selection, and final part characteristics.

Advantages of CNC Turning

CNC turning offers several benefits:

- Precision: Achieves tight tolerances for high-accuracy parts.

- Efficiency: Automated processes reduce production time.

- Versatility: Handles various materials and part geometries.

- Repeatability: Ensures consistent quality across multiple units.

- Safety: Enclosed cutting areas minimize operator risk.

Limitations of CNC Turning

Despite its strengths, CNC turning has limitations:

- Shape Constraints: Best suited for axially symmetric parts; complex 3D geometries may require CNC milling.

- Initial Investment: High costs for machines and software.

- Skill Requirements: Needs trained operators and programmers.

Applications of CNC Turning

CNC turning is integral to numerous industries:

- Automotive: Produces shafts, gears, and bushings.

- Aerospace: Crafts turbine blades, engine mounts, and landing gear components.

- Medical: Manufactures surgical tools and implants with stringent precision.

- Electronics: Creates connectors and housings for devices.

- Industrial Machinery: Fabricates large gears, flywheels, and structural components.

CNC Turning vs. Other Processes

Compared to CNC milling, which uses a rotating tool on a stationary workpiece to create complex 3D shapes, CNC turning is specialized for cylindrical parts with smoother finishes and simpler setups. For high-volume plastic parts, injection molding may be more cost-effective, while die casting suits large-scale metal components. 3D printing is ideal for rapid prototyping but lacks the durability of turned parts.

Conclusion

CNC turning is a powerful, precise manufacturing process that transforms raw materials into high-quality, cylindrical components. Its automation, versatility, and accuracy make it indispensable for industries requiring reliable, repeatable production. By understanding its mechanics, operations, and applications, you can determine if CNC turning is the right choice for your project. For professional CNC turning services, providers like 3ERP and Fictiv offer advanced capabilities to bring your designs to life with precision and efficiency.

Leave a Reply